PIPEWORK

Project Design and Installation

We can design, fabricate, and install process pipework systems supported by our qualified team

PROVIDING

Effective Solutions

From concept to coded pipework to final quality control and documentation, our team is both qualified and experienced

PIPEWORK

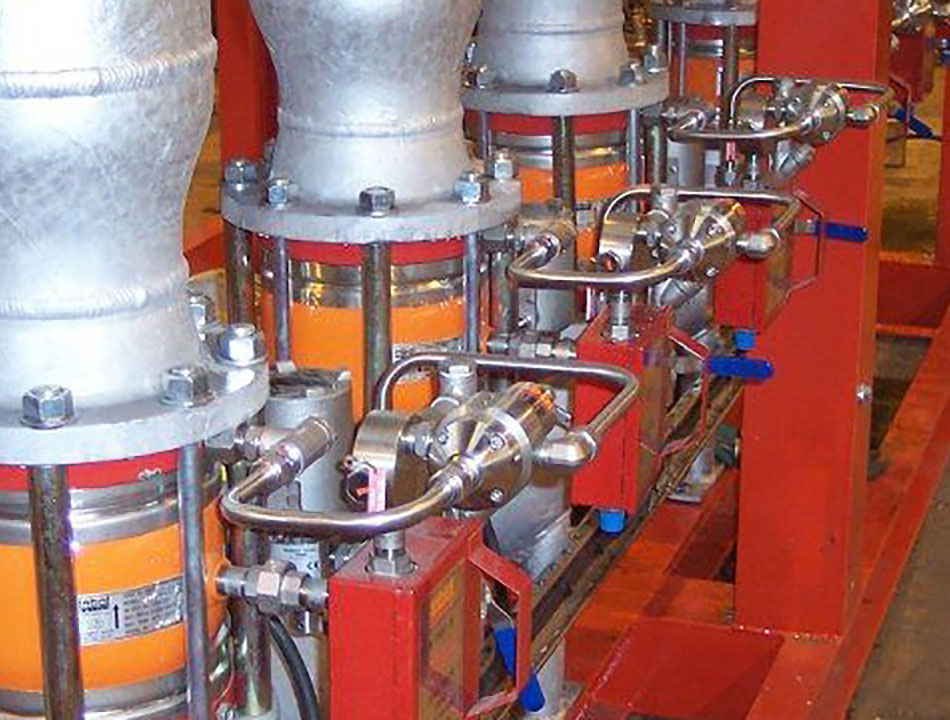

Coded Pipework

We supply prefabricated pipework in carbon and stainless steel, duplex, hastelloy and cunifer. Typical applications would be pipe spools, jacketed pipework or screwed pipework as commonly found in the oil & gas industries.

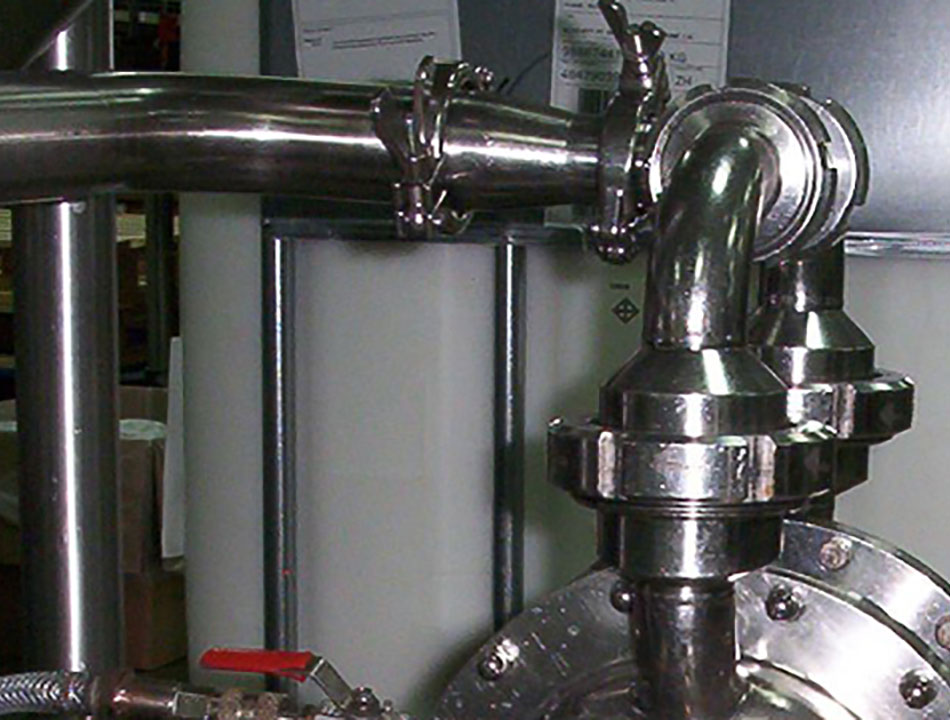

Hygienic Pipework

Fabricated in thin wall stainless steel tube with varying degrees of surface and internal finishes using orbital or manual tungsten inert gas techniques. Typical applications would be processed pipework systems incorporating purified water, WFI, SCIP, high purity steam. Commonly found in the dairies, breweries, soft drinks, food, pharmaceutical, confectionery and chemical industries.

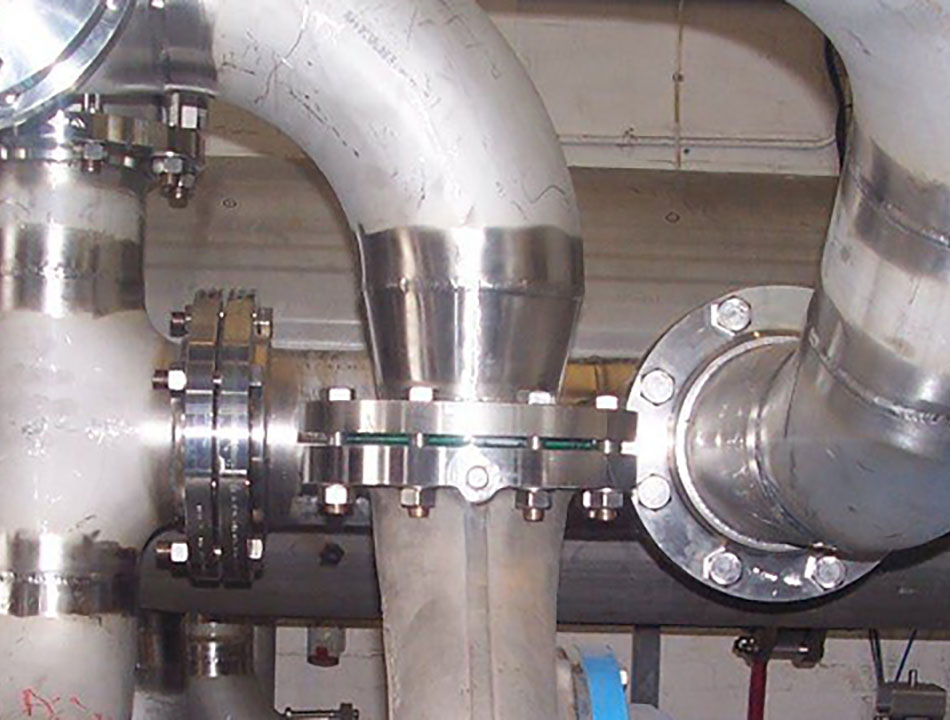

Process and Mechanical Pipework

Fabrication and installation of all utility pipework (coded welders). Typical Applications being pipework systems for all industries, tubular structures, hand rails, factory services pipework including water, steam, condensate, glycol and chilled water.

Quality Control

We offer a variety of quality documentation i.e. full weld traceability, welder certification to ASME IX, BS EN 15614, ISO 9606-1, material certification, PH testing, non destructive metrology testing, pressure testing and as built drawings.

Orbital Welding

Our orbital welding facilities deliver very high quality welds. Orbital welding can be the only means to reach weld quality requirements for the pharmaceutical and petrochemical industries. The use of portable orbital welding machines can also be very useful where access space is limited.